Views: 365 Author: Lasting titanium Publish Time: 2025-10-31 Origin: Site

Content Menu

● Understanding Titanium Pipe Fittings

● Exceptional High-Temperature Performance

● Improved Mechanical Strength

>> 1. What are the specific temperature ranges where titanium pipe fittings excel?

>> 2. How does titanium's corrosion resistance compare to stainless steel in high-temperature systems?

>> 3. What industries benefit most from using titanium pipe fittings in high-temperature applications?

>> 4. Are titanium pipe fittings more expensive than traditional materials?

>> 5. What are the advantages of using titanium fittings in high-pressure environments?

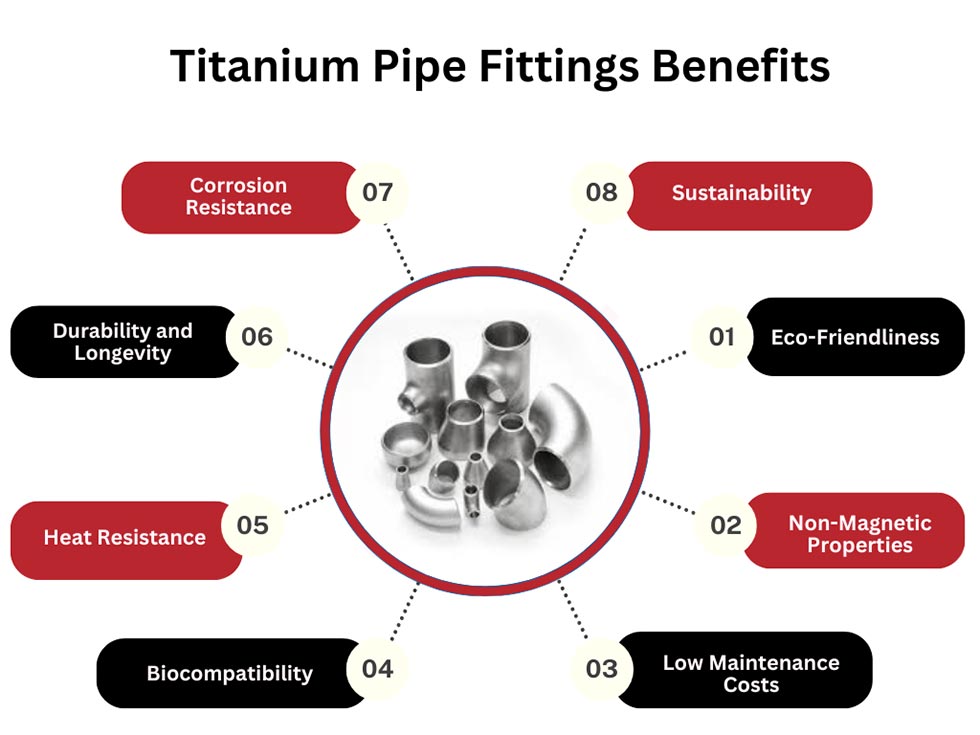

Titanium pipe fittings have gained significant recognition in various industries, particularly for their performance in high-temperature systems. This article explores the numerous benefits of using titanium pipe fittings, highlighting their unique properties, applications, and advantages over traditional materials.

Titanium is a metal known for its exceptional strength, lightweight nature, and remarkable resistance to corrosion. These properties make titanium an ideal choice for pipe fittings used in high-temperature applications, where materials are often subjected to extreme conditions. The use of titanium in high-temperature systems spans various industries, including aerospace, power generation, and chemical processing, making it a versatile material in the industry.

Titanium's unique characteristics stem from its atomic structure, which allows it to form a stable oxide layer when exposed to oxygen. This oxide layer acts as a protective barrier, preventing further corrosion and degradation. As a result, titanium fittings are not only lightweight but also incredibly resilient, making them suitable for demanding high-temperature environments.

Titanium pipe fittings are designed to perform exceptionally well in high-temperature environments. They can maintain their strength and structural integrity at temperatures exceeding 600°C (1112°F). This capability is particularly beneficial in industries such as power generation, petrochemicals, and aerospace, where systems often operate under extreme conditions.

The ability of titanium to withstand high temperatures without deforming or losing strength ensures the reliability of piping systems. This reliability is crucial in preventing failures that could lead to costly downtime and repairs. In applications involving steam or hot gases, titanium fittings provide a level of performance that is often unmatched by other materials.

Moreover, titanium's high melting point allows it to maintain its mechanical properties even in extreme heat, making it suitable for applications that involve high-pressure steam or hot fluid transport. This characteristic ensures that the fittings remain reliable and effective, contributing to the overall longevity of the system.

One of the standout features of titanium is its remarkable resistance to corrosion. In high-temperature systems, where exposure to corrosive substances is common, titanium fittings excel. Unlike traditional materials such as steel, which can rust and degrade, titanium forms a protective oxide layer that shields it from corrosion.

This corrosion resistance extends the lifespan of titanium fittings, reducing the need for frequent replacements and maintenance. In industries where downtime is costly, the durability of titanium fittings can lead to significant savings over time. The low maintenance requirements of titanium fittings mean that they can operate effectively without the need for regular repainting or protective coatings, which are often necessary for other materials.

In addition to its resistance to corrosion from seawater and chemicals, titanium also withstands high-temperature oxidation. This property is particularly important in high-temperature applications, where other materials may fail due to oxidation. The ability to resist corrosion and oxidation ensures that titanium fittings maintain their integrity and performance over extended periods, even in harsh environments.

The lightweight nature of titanium fittings offers several advantages in high-temperature applications. Reducing the weight of piping systems can enhance overall efficiency and performance. In aerospace and automotive applications, for instance, every ounce counts, and using lightweight materials like titanium can lead to improved fuel efficiency and performance.

Additionally, the lightweight design of titanium fittings makes them easier to handle and install. This can lead to reduced labor costs and improved safety during installation and maintenance. The ease of handling is particularly beneficial in high-temperature systems, where the risk of accidents can increase due to the complexity of the installation process.

The lightweight nature of titanium also allows for more efficient designs in piping systems. Engineers can create systems that require less support and fewer structural reinforcements, leading to overall cost savings in both materials and labor. This efficiency is especially valuable in industries where space is limited, and weight reduction is critical for performance.

Titanium fittings exhibit superior mechanical strength compared to many other materials. This strength is particularly important in high-temperature systems, where fittings must withstand not only heat but also pressure and stress. The high strength of titanium allows for larger cross-sectional areas in pipes, resulting in less pressure drop when fluids are transported.

This characteristic is especially valuable in applications involving steam or hot gases, where other materials may weaken or deform. By using titanium fittings, companies can ensure the integrity of their piping systems, reducing the risk of failures and costly shutdowns. The mechanical strength of titanium also contributes to its ability to withstand thermal cycling, which is common in high-temperature applications.

In addition to its strength, titanium's resistance to fatigue and deformation makes it an ideal choice for high-pressure applications. The ability to maintain structural integrity under repeated stress cycles ensures that titanium fittings can perform reliably over time, even in demanding environments.

Titanium's ability to withstand thermal shock is another significant advantage in high-temperature applications. Thermal shock occurs when materials are subjected to rapid temperature changes, which can lead to cracking or failure. Titanium's excellent thermal shock resistance allows it to maintain its mechanical properties even under extreme temperature fluctuations.

This property is particularly beneficial in industries where equipment may experience sudden changes in temperature, such as in power generation or chemical processing. By using titanium fittings, companies can enhance the reliability and safety of their systems, ensuring that they can operate effectively in a wide range of conditions.

The thermal shock resistance of titanium also contributes to its longevity in high-temperature applications. By minimizing the risk of thermal-related failures, titanium fittings help ensure that piping systems remain operational and efficient, reducing the need for costly repairs and replacements.

https://www.lastingtitanium.com/titanium-pipe-fittings.html

https://www.lastingtitanium.com/titanium-pipe-fittings.html

While titanium fittings may have a higher initial cost compared to traditional materials, their long-term benefits often outweigh the upfront investment. The durability and corrosion resistance of titanium lead to lower maintenance costs and extended service life, making them a cost-effective choice for high-temperature applications.

Over time, the savings associated with reduced maintenance and replacement can be substantial. In critical applications where reliability is essential, the use of titanium fittings is justified despite the higher initial costs. The peace of mind that comes with knowing that equipment is built to withstand harsh conditions and perform reliably is invaluable in the high-temperature systems.

Moreover, the long-term performance of titanium fittings can lead to improved operational efficiency. By reducing the frequency of repairs and replacements, companies can allocate resources more effectively, focusing on other areas of their operations. This efficiency contributes to the overall success of high-temperature systems, enhancing productivity and profitability.

Titanium pipe fittings are versatile and can be used in a wide range of high-temperature applications. They are commonly found in:

- Power Generation: Used in steam and gas turbines, heat exchangers, and cooling systems. The ability of titanium to withstand high temperatures and pressures makes it ideal for these applications, where reliability is crucial.

- Chemical Processing: Ideal for handling corrosive chemicals at elevated temperatures. Titanium's resistance to corrosion ensures that it can maintain its integrity in harsh chemical environments, contributing to the safety and efficiency of chemical processing systems.

- Aerospace: Utilized in aircraft engines, fuel systems, and exhaust systems. The lightweight and high-strength properties of titanium make it a preferred choice in aerospace applications, where performance and safety are paramount.

- Marine Applications: Employed in seawater cooling systems and offshore oil and gas extraction. The corrosion resistance of titanium is particularly beneficial in marine environments, where exposure to saltwater can lead to rapid degradation of traditional materials.

The versatility of titanium fittings makes them suitable for various industries, enhancing their appeal as a reliable choice for high-temperature systems.

Titanium pipe fittings offer numerous benefits in high-temperature systems, including exceptional performance, corrosion resistance, lightweight design, and long-term cost savings. Their ability to withstand extreme conditions makes them a preferred choice in industries such as power generation, aerospace, and chemical processing. By investing in titanium fittings, companies can enhance the reliability and efficiency of their piping systems, ultimately leading to improved operational performance.

Titanium pipe fittings excel in high-temperature environments, maintaining their strength and integrity at temperatures exceeding 600°C (1112°F).

Titanium exhibits superior corrosion resistance compared to stainless steel, particularly in high-temperature and corrosive environments, making it a more reliable choice for demanding applications.

Industries such as power generation, aerospace, chemical processing, and marine applications benefit significantly from using titanium pipe fittings due to their durability and performance under extreme conditions.

Yes, titanium pipe fittings typically have a higher initial cost, but their long-term durability and reduced maintenance needs can lead to significant cost savings over time.

Titanium fittings offer high strength, lightweight design, and resistance to extreme conditions, making them ideal for high-pressure applications where reliability and safety are critical.

This technical analysis explores the application of titanium square bars (specifically Ti-6Al-4V) in the automotive sector. It details the material's metallurgical advantages, its role in improving NVH performance compared to steel, and its economic value in EV weight reduction. The article also provides professional insights into CNC machining, advanced joining methods like Electron Beam Welding, and the strategic importance of square bar geometries in modern vehicle engineering. (415 characters)

This technical guide explores the complexities of titanium square bar standards (ASTM B348, AMS 4928) and manufacturing processes. It delves into the chemistry of Alpha Case formation, the advantages of Grade 12 as a Pd-free alternative, and the necessity of PAUT/Immersion testing to solve corner "dead zones" in square profiles. Aimed at industry professionals, the article clarifies the differences between rolled and forged bars while emphasizing microstructural integrity, including primary alpha morphology and prior-beta grain refinement, for high-performance applications.

This technical analysis explores the metallurgical and mechanical advantages of using Titanium Square Bars (ASTM F136/F67) in medical device manufacturing. It highlights how square profiles improve CNC machining stability, reduce material waste, and enhance the fatigue life of implants through refined forging and superior microstructural homogeneity. By focusing on interstitial control and substrate purity, this guide illustrates why square bar stock is the strategic "Gold Standard" for high-precision orthopedic and spinal applications.

This article discusses the essential certifications for titanium pipe fittings, including ASTM and ASME standards, API certification, CE marking, NACE certification, ISO 9001, NADCAP accreditation, and material certification. It emphasizes the importance of these certifications in ensuring quality, safety, and compliance in various applications, particularly in aerospace, chemical processing, and marine industries.

This article explores the reasons aerospace OEMs rely on titanium fasteners, highlighting their unique properties such as strength-to-weight ratio, corrosion resistance, and high-temperature tolerance. It discusses applications in structural components, compatibility with composites, and the economic impact of titanium fasteners. The article also addresses challenges in manufacturing and supply chain management while looking ahead to innovations and sustainability in the titanium industry.

This article provides a comprehensive guide on identifying high-quality titanium fasteners from reliable suppliers. It covers key characteristics of quality fasteners, supplier evaluation criteria, and quality assurance practices essential for ensuring safety and performance in various applications. By following these guidelines, industry professionals can make informed decisions when sourcing titanium fasteners.

This article explores the top five applications where titanium fasteners are essential, including aerospace, marine engineering, chemical processing, automotive, and medical devices. It highlights the unique properties of titanium fasteners that make them suitable for harsh environments and discusses their benefits in various industries.

This article explores how titanium fasteners reduce maintenance costs in harsh environments. It highlights their unique properties, applications in various industries, and the economic advantages they offer. Despite higher initial costs, the long-term savings and reliability make titanium fasteners a preferred choice for demanding applications.

This article explores the investment value of titanium fasteners for long-term performance, highlighting their unique properties, applications, and cost considerations. It emphasizes the advantages of titanium fasteners, including corrosion resistance, durability, and weight savings, while addressing challenges such as initial cost, machining difficulties, and thread galling. The article concludes with practical insights and frequently asked questions to assist industry professionals in making informed decisions regarding titanium fasteners.

This article explores the environmental benefits of using titanium round bars in manufacturing, highlighting their unique properties, applications, and contributions to sustainability. It emphasizes reduced waste generation, energy efficiency, and recyclability, while addressing challenges such as initial cost and machining difficulties. The article concludes with practical insights into the role of titanium in promoting eco-friendly manufacturing practices.

This guide explores the investment potential of titanium square bars, highlighting their unique properties, applications, and cost considerations. It emphasizes the long-term value of titanium in various industries, including aerospace, medical, and marine, while addressing challenges in sourcing and machining. The article concludes with practical advice for selecting suppliers and understanding the benefits of investing in titanium square bars.

This article provides an in-depth overview of titanium square bar specifications, covering material grades, standards, dimensions, surface finishes, and applications. It highlights the importance of understanding these specifications before purchasing, ensuring informed decisions for various industrial applications.

This article explores the top five applications of titanium and titanium alloy square bars in modern engineering, highlighting their significance in aerospace, medical devices, automotive, marine, and chemical processing industries. The unique properties of titanium, such as high strength-to-weight ratio and corrosion resistance, make it an essential material for innovative engineering solutions.

This article explores the global demand for high-grade titanium wire, focusing on key industries, regional demand, technological innovations, and challenges. It highlights the importance of titanium wire in aerospace, medical, and chemical processing sectors, emphasizing the need for manufacturers to adapt to evolving market dynamics.

This article explores the superiority of titanium wire in chemical processing industries, highlighting its exceptional corrosion resistance, mechanical properties, cost-effectiveness, and environmental benefits. It discusses various applications and use cases, emphasizing the material's role in enhancing equipment longevity and reliability.

This article provides a comprehensive guide on selecting the right titanium wire for industrial applications. It covers essential factors such as application requirements, titanium grades, diameter considerations, and manufacturing processes. The article also highlights the various applications of titanium wire in industries like aerospace, medical, chemical processing, and marine. By understanding these aspects, industry professionals can make informed decisions when choosing titanium wire for their projects.

This article explores the key benefits of using titanium square bars in marine projects, highlighting their exceptional corrosion resistance, high strength-to-weight ratio, biocompatibility, and durability. The versatility of titanium square bars makes them suitable for various marine applications, contributing to long-term cost-effectiveness and environmental sustainability. Investing in titanium ensures superior performance and longevity in marine operations.

This article explores the pros and cons of titanium tubes versus nickel alloy tubes for industrial use. It highlights the unique properties, advantages, and disadvantages of each material, along with their applications in various industries. The choice between these materials depends on specific application requirements, including cost, strength, and corrosion resistance.

This article explores the advantages of titanium tubes in aerospace fuel lines, highlighting their high strength-to-weight ratio, corrosion resistance, and thermal stability. It discusses their applications in fuel systems, hydraulic systems, and engine components, while also considering the future of titanium in aerospace, including innovations in manufacturing and expanding applications.

This article provides a comprehensive guide on how to inspect the quality of titanium tubes before purchasing. It covers essential inspection methods, including visual checks, documentation verification, and non-destructive testing. Additionally, it emphasizes the importance of supplier reputation and adherence to quality standards, ensuring that buyers make informed decisions in the titanium industry.