Views: 265 Author: Lasting titanium Publish Time: 2025-10-22 Origin: Site

Content Menu

● The Unique Properties of Titanium

● Applications of Shaanxi Lasting Titanium Round Bars

● Competitive Advantages of Shaanxi Lasting Titanium

● Innovations in Titanium Processing

>> Advanced Manufacturing Techniques

>> Partnerships and Collaborations

>> Q1: What specific titanium alloys does Shaanxi Lasting Titanium offer for round bars?

>> Q2: How does Shaanxi Lasting Titanium ensure traceability of their titanium round bars?

>> Q3: What are the typical lead times for custom orders of Shaanxi Lasting Titanium round bars?

>> Q4: Are Shaanxi Lasting Titanium round bars suitable for high-temperature applications?

>> Q5: What industries benefit the most from using Shaanxi Lasting Titanium round bars?

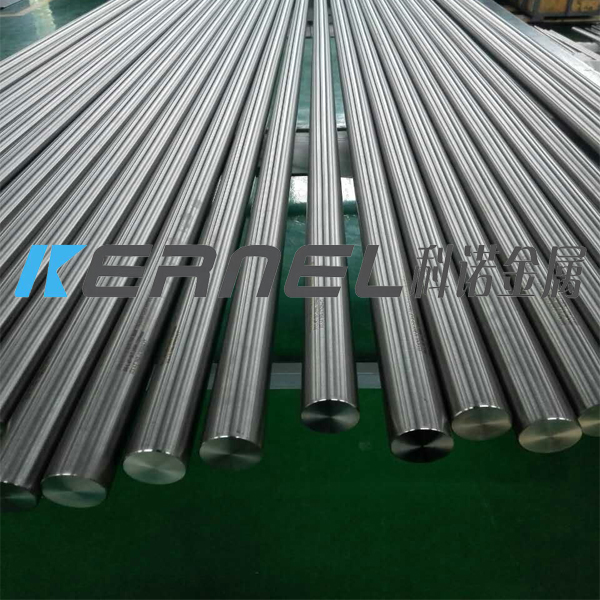

Shaanxi Lasting Titanium is a prominent manufacturer of titanium round bars, recognized for their exceptional quality and performance across various industries. This article delves into the unique features and advantages of Shaanxi Lasting Titanium round bars, highlighting why they stand out in the global market. With a commitment to innovation and quality, Shaanxi Lasting Titanium has positioned itself as a leader in the titanium industry, catering to the needs of diverse sectors.

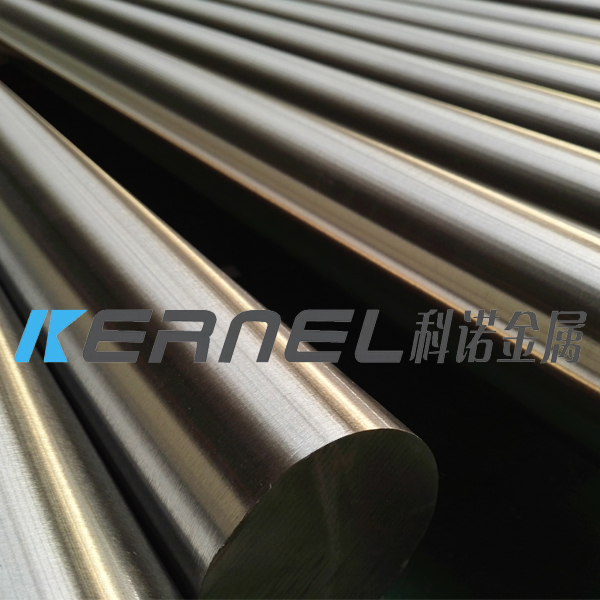

Titanium is renowned for its remarkable strength-to-weight ratio, making it a preferred material in many high-performance applications. It is stronger than steel yet significantly lighter, which is crucial in industries such as aerospace and automotive, where reducing weight can lead to improved fuel efficiency and performance. The inherent strength of titanium allows for the design of thinner, lighter components without compromising structural integrity. This property not only enhances the performance of aircraft and vehicles but also contributes to overall energy savings, making titanium a sustainable choice for manufacturers.

One of the standout features of titanium is its exceptional resistance to corrosion. Titanium round bars can withstand harsh environments, including exposure to saltwater, acids, and other corrosive substances. This makes them suitable for marine applications, chemical processing, and medical devices. The ability of titanium to form a protective oxide layer when exposed to oxygen further enhances its corrosion resistance, ensuring longevity and reliability in demanding conditions. This characteristic is particularly valuable in industries where equipment failure due to corrosion can lead to significant downtime and financial losses.

Titanium is biocompatible, meaning it is safe for use in medical applications. Shaanxi Lasting Titanium round bars are often used in surgical implants, dental devices, and other medical equipment, ensuring patient safety and comfort. The biocompatibility of titanium minimizes the risk of adverse reactions in the human body, making it an ideal choice for implants that require long-term stability. This property has led to the widespread adoption of titanium in the medical field, where reliability and safety are paramount.

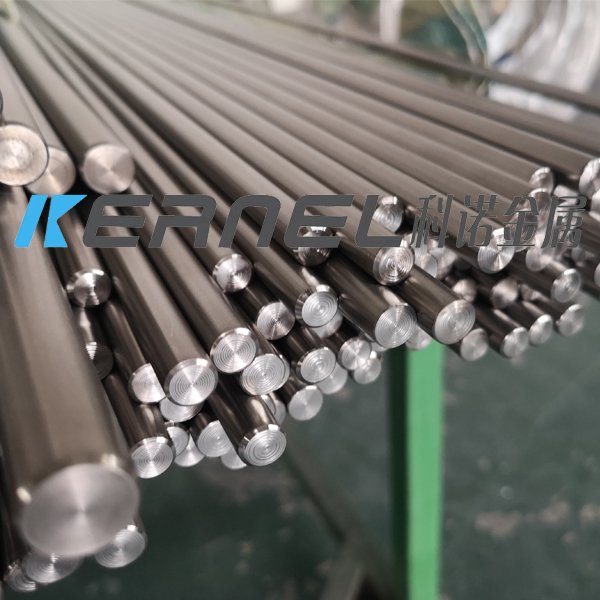

In the aerospace sector, titanium round bars are used for manufacturing aircraft components, including frames, engine parts, and landing gear. Their lightweight and strong properties contribute to the overall efficiency and safety of aircraft. The use of titanium in aerospace applications not only enhances performance but also reduces fuel consumption, which is a critical factor in the industry's push for sustainability. As airlines and manufacturers seek to lower their carbon footprints, the demand for lightweight materials like titanium continues to grow.

The medical industry benefits significantly from titanium's biocompatibility and corrosion resistance. Shaanxi Lasting Titanium round bars are utilized in various medical devices, such as joint replacements and dental implants, ensuring longevity and reliability. The ability of titanium to integrate seamlessly with human tissue further enhances its appeal in medical applications. As the healthcare sector continues to innovate, the demand for high-quality titanium components is expected to rise, driven by advancements in surgical techniques and implant technologies.

Due to their corrosion resistance, titanium round bars are ideal for marine applications. They are used in shipbuilding, offshore platforms, and underwater systems, providing durability and safety in demanding oceanic conditions. The marine environment poses unique challenges, including exposure to saltwater and biofouling, which can degrade traditional materials. Titanium's resistance to these factors ensures that components maintain their integrity over time, reducing maintenance costs and enhancing the safety of marine operations.

Shaanxi Lasting Titanium adheres to stringent quality control measures, ensuring that every batch of titanium round bars meets international standards. This commitment to quality has earned them a reputation as a trusted supplier worldwide. The company employs advanced testing methods to assess the mechanical properties and chemical composition of their products, ensuring consistency and reliability. By maintaining high standards throughout the manufacturing process, Shaanxi Lasting Titanium can confidently guarantee the performance of their products in critical applications.

The company offers a range of customization options for their titanium round bars, allowing clients to specify dimensions, grades, and finishes according to their unique requirements. This flexibility makes Shaanxi Lasting Titanium a preferred choice for many industries. Whether a client needs a specific diameter, length, or surface finish, the company can accommodate these requests, ensuring that customers receive products tailored to their specific applications. This level of customization not only enhances customer satisfaction but also fosters long-term partnerships with clients.

While titanium may have a higher initial cost compared to other metals, its durability and longevity make it a cost-effective choice in the long run. Shaanxi Lasting Titanium round bars require less frequent replacement, leading to lower overall costs for businesses. Additionally, the reduced maintenance and downtime associated with titanium components contribute to significant savings over time. As industries increasingly focus on total cost of ownership, the economic advantages of using titanium are becoming more apparent.

Shaanxi Lasting Titanium employs advanced manufacturing techniques to produce high-quality titanium round bars. These methods enhance the material properties and ensure consistency in production, making their products stand out in the market. The use of state-of-the-art equipment and processes allows the company to achieve precise tolerances and superior surface finishes, which are critical for applications in aerospace and medical fields. Continuous investment in technology ensures that Shaanxi Lasting Titanium remains competitive in a rapidly evolving industry.

The company invests in research and development to explore new applications and improve existing products. This commitment to innovation keeps Shaanxi Lasting Titanium at the forefront of the titanium industry. By collaborating with research institutions and industry partners, the company is able to stay ahead of market trends and develop solutions that meet the evolving needs of their customers. This proactive approach to R&D not only enhances product offerings but also positions Shaanxi Lasting Titanium as a thought leader in the titanium sector.

Shaanxi Lasting Titanium has established a strong global presence, exporting their products to various countries. Their ability to meet international standards and customer expectations has made them a preferred supplier in the global market. The company has developed a robust distribution network that enables efficient delivery of products to clients around the world. This global reach not only expands their market opportunities but also enhances their reputation as a reliable supplier of high-quality titanium products.

The company collaborates with various industries, including aerospace, medical, and marine, to develop tailored solutions that meet specific needs. These partnerships enhance their market reach and product offerings. By working closely with clients, Shaanxi Lasting Titanium can gain valuable insights into industry trends and customer preferences, allowing them to adapt their products and services accordingly. This collaborative approach fosters innovation and drives mutual success for both the company and its partners.

Shaanxi Lasting Titanium round bars stand out in the global market due to their unique properties, diverse applications, and commitment to quality. Their strength, durability, and corrosion resistance make them an ideal choice for various industries, while their innovative manufacturing techniques and customization options ensure they meet the evolving needs of their clients. As the demand for high-performance materials continues to grow, Shaanxi Lasting Titanium is well-positioned to lead the way in the titanium industry.

A1: Shaanxi Lasting Titanium offers a variety of titanium alloys, including commercially pure titanium grades and titanium alloys such as Ti-6Al-4V, which is widely used in aerospace and medical applications.

A2: The company maintains comprehensive documentation and testing records for each batch of titanium round bars, ensuring complete traceability from raw material sourcing to final product delivery.

A3: Lead times for custom orders can vary based on the complexity of the specifications and current production schedules, but the company typically aims to deliver within a few weeks.

A4: Yes, titanium round bars are suitable for high-temperature applications due to their excellent thermal stability and resistance to oxidation, making them ideal for use in aerospace and industrial settings.

A5: Industries such as aerospace, medical, marine, and chemical processing benefit significantly from using Shaanxi Lasting Titanium round bars due to their unique properties and performance advantages.

This article explores the best titanium tubes for aerospace applications in 2025, detailing their properties, advantages, and key suppliers. It highlights the importance of titanium in the aerospace industry and discusses future trends, including innovations in manufacturing and sustainability. Understanding these aspects can help buyers make informed decisions in various aerospace applications.

This comprehensive guide explores how titanium sheets differ from other metal sheets, detailing their properties, applications, and considerations for buyers. It highlights the importance of selecting the right grade and supplier while discussing future trends in the titanium industry. Understanding these aspects can help buyers make informed decisions in various applications.

This comprehensive guide explores titanium sheets, detailing their properties, applications, manufacturing processes, and considerations for buyers. It highlights the importance of selecting the right grade and supplier while discussing future trends in the titanium industry. Understanding these aspects can help buyers make informed decisions in various applications.

This article explores best practices from top titanium sheet producers to ensure quality, covering aspects such as raw material selection, quality control measures, advanced manufacturing techniques, and surface treatments. It highlights the importance of technology in enhancing production efficiency and addresses common challenges faced in the industry.

This article explores the leading manufacturers of high-quality titanium sheets globally, highlighting their contributions to various industries. It discusses the unique properties of titanium sheets, their applications, and the factors that contribute to their quality. The article emphasizes the importance of titanium sheets in modern engineering and manufacturing, providing insights into their role in aerospace, marine, medical, and chemical processing applications.

This article explores the significance of titanium sheets for corrosion resistance, highlighting their unique properties, applications, and the factors that contribute to their performance. It discusses the various grades of titanium, maintenance practices, and the industries that benefit from using titanium sheets, emphasizing their role in modern engineering and manufacturing.

This article explores the significance of titanium pipe fittings in medical equipment, highlighting their biocompatibility, corrosion resistance, and low maintenance needs. It discusses their applications in surgical instruments, implants, and pharmaceutical manufacturing, while also addressing future trends and innovations in the field.

This article discusses how titanium pipe fittings minimize maintenance costs through their exceptional corrosion resistance, reduced maintenance requirements, and longevity. It highlights their applications in various industries, including chemical processing and marine environments, and emphasizes the cost-effectiveness of investing in titanium fittings. The strategic use of titanium in piping systems not only contributes to cost savings but also supports sustainable practices by reducing waste and the need for frequent replacements.

This article explores the top exporters of titanium pipe fittings to the US and Europe, highlighting key players like Titanium Industries and Alleima. It discusses the properties of titanium, market trends, and challenges faced by exporters, emphasizing the growing demand in aerospace and medical applications. The future of titanium pipe fittings looks promising, with ongoing innovations and a commitment to sustainability paving the way for new opportunities.

This article examines the lifecycle of titanium pipes in harsh environments, highlighting their unique properties, production processes, and applications. It discusses the advantages and challenges of using titanium pipes and explores future trends in titanium technology. As industries evolve, titanium pipes will continue to play a vital role in enhancing performance and sustainability across various sectors.

This article discusses titanium pipe welding techniques, highlighting their importance in producing high-quality components for various industries. It covers the advantages and challenges of welding titanium, the role of advanced manufacturing processes, and future trends in titanium processing. As technology advances, titanium will continue to play a vital role in enhancing performance across multiple sectors.

This article discusses the advantages of using forged titanium in chemical processing equipment, highlighting its strength, corrosion resistance, and durability. It explores various applications, economic benefits, and environmental considerations, making forged titanium a superior choice for the industry.

This article outlines best practices for sourcing high-quality titanium forgings, emphasizing the importance of defining requirements, researching suppliers, evaluating capabilities, and ensuring compliance with industry standards. By following these guidelines, manufacturers can secure reliable and high-performance titanium components for their applications

Content Menu● Why Attend?>> What to Expect from Lasting Titanium● Networking Opportunities● Industry Trends● Join Us!● Detailed Overview of the Event>> Event Highlights>> Sustainability Focus● Lasting Titanium's Commitment to Innovation>> Our Product Range>> Research and Development● ConclusionLasti

This article explores the environmental benefits of using titanium tubes in industrial applications, highlighting their corrosion resistance, lightweight nature, and recyclability. It discusses their applications in various sectors, including aerospace, energy, and medical fields, while addressing challenges in production. The article emphasizes the role of titanium tubes in promoting sustainability and reducing environmental impacts.

This article examines how China's titanium sheet industry competes globally, highlighting its strengths, challenges, and future outlook. It discusses the significance of advanced manufacturing technologies like Vacuum Arc Remelting and free forging presses in enhancing titanium quality. As the industry evolves, it faces opportunities and challenges that will shape its role in the global market.

This article explores the significance of Vacuum Arc Remelting (VAR) and free forging presses in titanium sheet production. It highlights their roles in enhancing the quality and performance of titanium sheets, discusses the challenges faced in production, and examines future trends in titanium processing. As technology advances, these processes will continue to play a vital role in various industries.

This article explores how advanced forging and rolling techniques improve the quality of titanium sheets, highlighting their unique properties, advantages, and applications. It discusses the challenges faced in titanium processing and the future trends in the industry, including additive manufacturing and sustainability initiatives. As technology advances, titanium will continue to play a vital role in enhancing performance across various sectors.

This article explores the advantages of titanium sheets in marine and offshore engineering, highlighting their exceptional corrosion resistance, lightweight nature, and durability. It discusses various applications of titanium in the marine industry and addresses the challenges associated with using titanium. The article concludes with frequently asked questions to enhance understanding of titanium's role in marine engineering applications

This article explores the corrosion resistance of titanium sheets in chemical processing, highlighting the mechanisms behind this property and the factors influencing corrosion. It discusses the various applications of titanium sheets in the industry and the advantages of using titanium as a material. The article concludes with frequently asked questions to enhance understanding of titanium's role in chemical processing applications.